Detra studies, develops, produces and markets marine propellers through a reliable and competent technological process.

Project Engineering

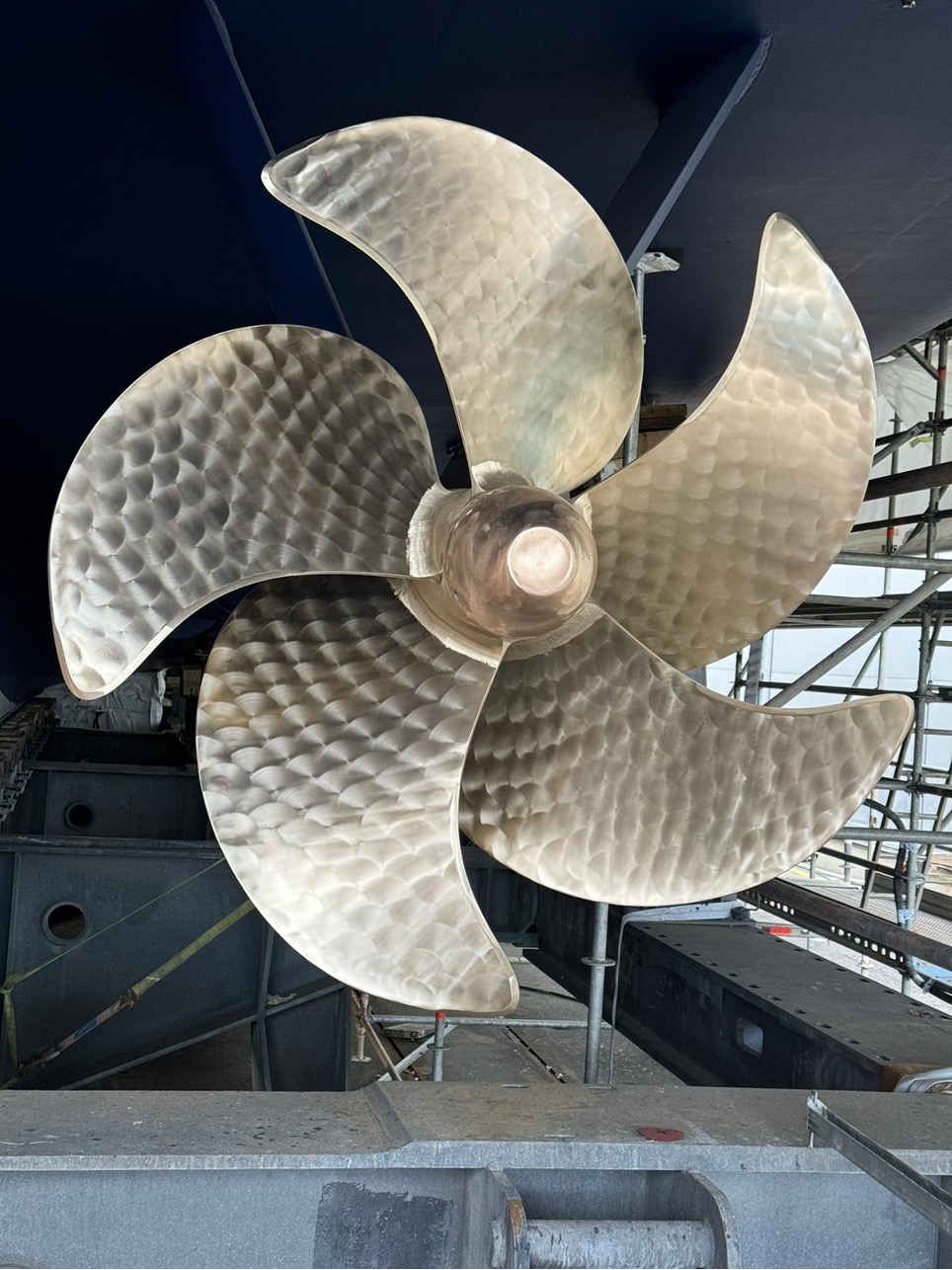

Our headquarter at Genova Port is dedicated to the manufacture of new propellers. Specifically, Detra can carry out several different operations, such as:

- Complete mechanical manufacturing of numerical controlled mechanical milling;

- Measuring and control of the shape via electronic tools, some of which where designed and realized by Detra;

- Manual finishing of blades and hub;

- Balancing of the propellers, both static and dynamic, on one or two shafts;

- CND controls by using penetrating liquids;

- GTAW and GMAW weldings on different materials, according to RINA, ABS and LRS approved procedures.

All these activities are performed in accordance with the international legislations for the ISO9001 quality control.

Production

People at Detra design and build custom propellers with a diameter up to 3 meters. The project includes different steps, which can be identified as follows:

- Project realization thanks to hydrodynamic computer software specific for each boat;

- Designing of the model with CAD 3D;

- 3D print of the model for the foundry.

Propeller measurement and optimization with 3D scanner directly in the port basin

Detra Srl offers a cutting-edge service for inspecting marine propellers without the need to remove them from the vessel. Thanks to our advanced 3D scanners, it is possible to precisely capture the dimensions and geometry of the propellers directly in the port basin, with millimetric accuracy.

This technology gives us the chance to:

- Analyze the efficiency and condition of the current propeller.

- Identify any deformations or wear.

- Provide data to optimize propeller performance or design a customized one.

- Restore the original geometry of the propeller.

Detra Srl’s service ensures fast turnaround times, precision, and a non-invasive approach, reducing costs and complications associated with propeller removal. A state-of-the-art solution to enhance your vessel’s performance and extend the lifespan of its propellers.

After-sales Department

Detra offers both engineering consultation and operational assistance, be it at headquarters, on the client’s premises or at the docks.

In order to do so, our after-sales service department can fix or modify propellers of every type and size, as well as shaft lines components.

Constant meetings with our clients are one of the guidelines we follow for every single one of our projects since the very first engineering phase. This is one of the things that allows us to always guarantee efficency, reliability and high standards.

Research and Innovation

We have specifically directed our researches on what follows:

- Multistage propellers;

- Automated manufacture of the built-up blades;

- Innovative technology for the 3D metallic print of the blades.

Moreover, our company recently successfully realised a project together with Azimut, Novigo, Engintec S.p.A. and the University of Genoa, after winning the European Regional Development Fund call for bids titled “Supporto alla realizzazione di progetti complessi di attività e di ricerca e sviluppo per le imprese aggregate ai poli di ricerca ed innovazione”, protocollo FILSE 0006806 del 17/04/2018.

Certifications

In 2024, Detra received both Rina 45001 and ISO 9001 Quality certifications.